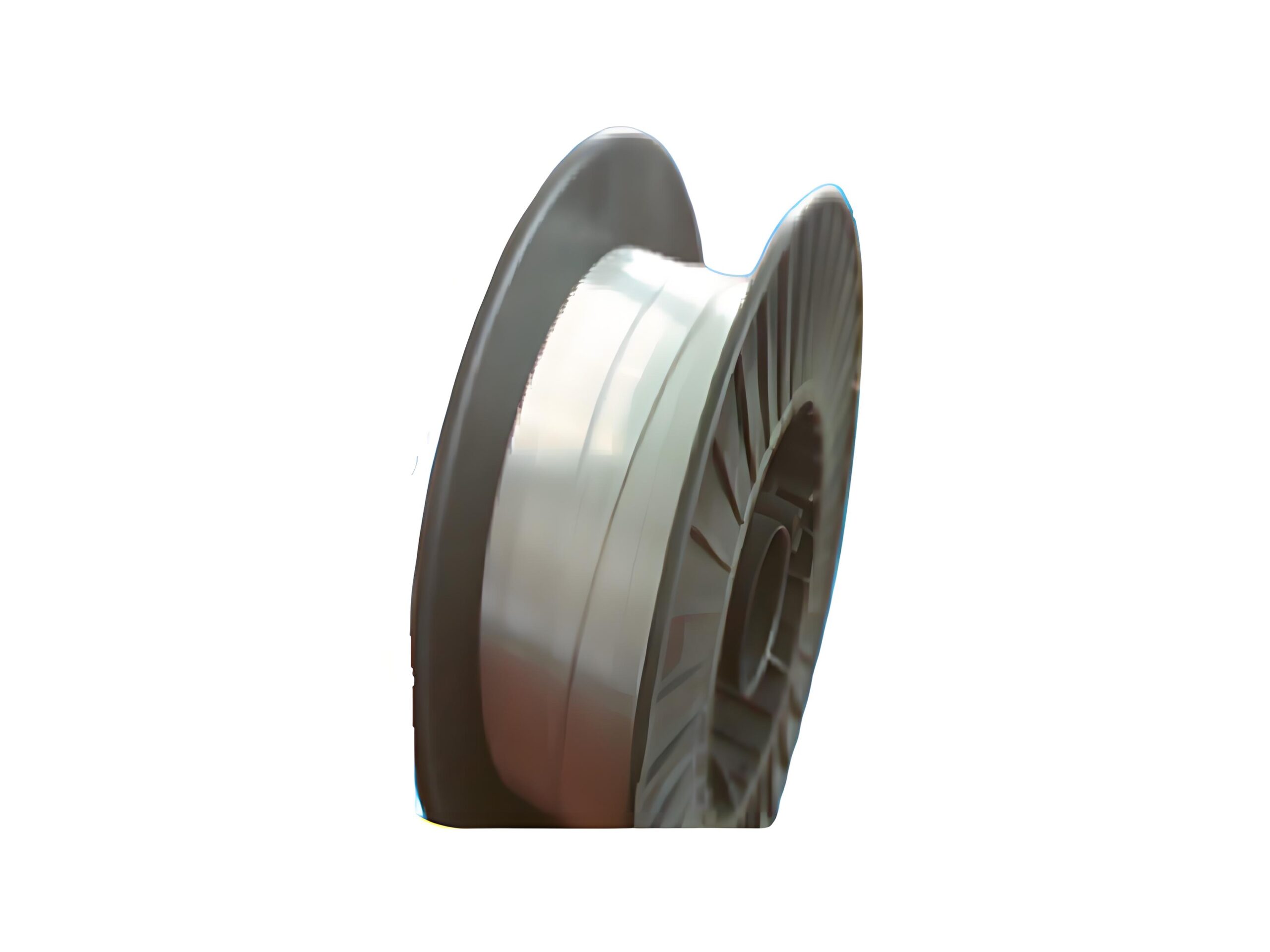

Flux-Cored Welding Wire

The steel belt is filled with the iron alloy powder of chromium, molybdenum, niobium etc.and makes the different diameters of welding wire after crimping and drawing. The flux-cored welding wires are widely used in the work pieces of cement, power roller, coal, engineering machinery, shield cutter, etc.

Hardfacing Material – Flux-Cored Welding Wire

Composition:

- Hard phase (chromium-containing iron-based alloy powder)

- Binder phase (low-carbon steel)

Specifications:

- Diameter: Φ1.6 mm, Φ2.0 mm, Φ2.4 mm, Φ3.2 mm, Φ4.0 mm

- Weld layer hardness: ≥55 HRC

Description

- The iron-based alloy powders(such as Cr,Mo etc.) are filled into the steel strip and then crimped and drawn intowelding wires of different diameters.

- The deposited metal is a high chromium alloy, which has toughness, crack resistance, peeling resistance, high heatresistance, and high wear resistanceafter work hardening. The material is easy to polish and cannot be processed.

- Used in the repair and remanufacturing of crusher rolls, percussion arms, hammers, picks, propellers, fan impellers,screen plates, liners etc.

Leave Your Message