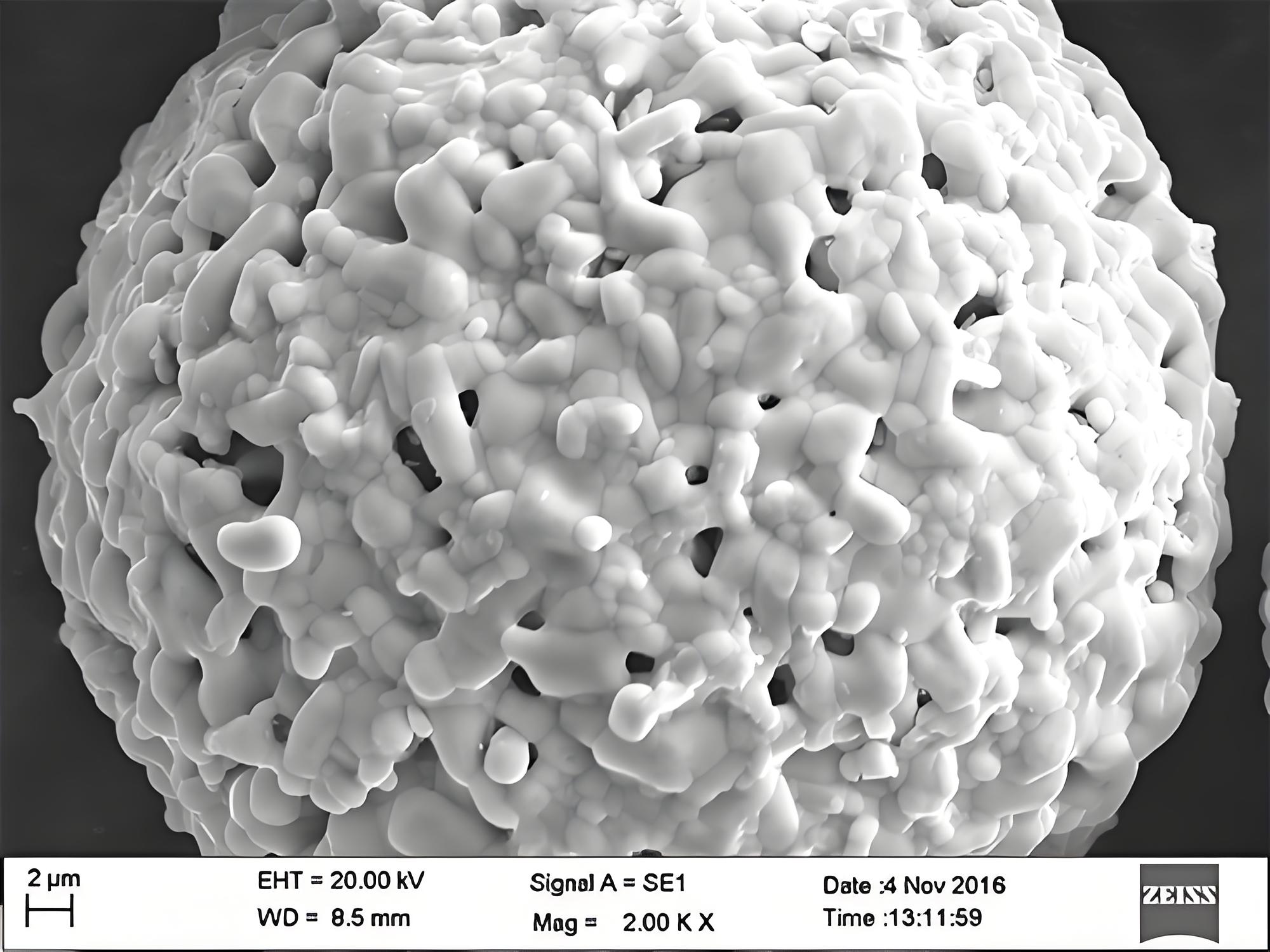

Cr3C2-Based Thermal Spray Powder

Thermal spray powder is used for High-Velocity Oxygen Fuel (HVOF) process. Molten or semi-molten materials are sprayed onto the workpiece surface by way of high temperature, high-velocity gas stream. This produces a dense coating which will increase the abrasive, erosive and corrosive resistance.

Applications:

- Thermal spray powders are used in the High-Velocity Oxygen Fuel (HVOF) process. Molten or semi-molten materials are sprayed onto the workpiece surface via a high-temperature, high-velocity gas stream, forming a dense coating that enhances the workpiece’s resistance to abrasion, erosion, and corrosion.

- During the spraying process, heat is partially transferred from the thermal spray powder to the relatively cool workpiece, resulting in minimal metallurgical changes to both the sprayed material and the workpiece. The coating bonds mechanically to the workpiece.

Agglomerated and Sintered Spray Powders

- WC-based:

86WC-10Co-4Cr (86/10/4), 88WC-12Co (88/12), 83WC-17Co (83/17), 73WC-20CrC-7Ni (73/20/7), 90WC-10Ni (90/10)

Cr3C2-based:

80Cr3C2-20NiCr (80/20), 75Cr3C2-25NiCr (75/25)

Crushed and Sintered Spray Powders

- 94WC-6Co, 86WC-10Co-4Cr (86/10/4), 88WC-12Co, 87WC-13Co

Particle Size

- (Applies to both agglomerated and sintered, and crushed and sintered powders)

-53+20 μm, -45+15 μm, -38+10 μm, -30+10 μm, and others.

Leave Your Message